Kaizen What is that? But has the power to make Toyota exist and develop for nearly 150 years without almost ever firing an employee? If you are looking for the answer to the above answer, then let's find out through the following article!

In this article, DPS will explain in detail to you the issues surrounding Kaizen in the following order:

- Kaizen What is that?

- Real story – Toyota applies Kaizen into administration.

- What are the benefits for businesses when applying? Kaizen?

- Steps to take Kaizen.

- Factors determining success when implementing the philosophy Kaizen.

- The principles of Kaizen What is the application?

1. What is Kaizen?

When it comes to quality improvement, you cannot ignore Japan. This is a country that is at the forefront of this ability. Quite a few businesses in Japan have successfully applied business philosophies and cultures. And Kaizen is one of them. So Kaizen What is that?

Kaizen is actually an economic term and originated in Japan. It is made up of two words. While “Kai” means change and the word “Zen” means better. Recap Kaizen means “change for the better” or you can interpret it as “continuous improvement”.

This is one of the famous business philosophies in the land of the rising sun since the 1950s (Álvarez-García, 2018). Kaizen It is not only successfully applied by businesses in Japan but also used worldwide. Therefore, this term is translated in English as “continuous improvement” (Carnerud, 2018) – “continuous improvement”.

Many people are still mistaken Kaizen with the term "Innovation" - "Innovation" in western countries. In fact, the change of Kaizen people-oriented, relatively small-scale improvements of incremental nature and achieving their goals over a long period of time. This is completely different from the "Innovation" that the West adopts.

2. Real story – Toyota applies Kaizen to management.

In the history of its formation and development, Toyota has experienced many events and difficulties faced many times. These can be mentioned as: the 2008 financial crisis or the heavy effects from the terrible earthquake in Japan and the historic tsunami in Thailand. However, even in the most difficult times and facing the risk of bankruptcy, Toyota still insists on maintaining the policy of "saying no to firing employees".

2.1. Accept to pay an additional $220 million/year in interest and would rather cut costs than cut staff.

During the Asian financial crisis in 1997, Toyota Thailand went through four consecutive years of losses without cutting jobs.

This decision was brought down from the person holding the highest position of Toyota at that time. It was President Hiroshi Okuda. Mr. Okuda ordered: "Cut all costs, but do not touch any people".

Because of this policy, in August 1998, Moddy downgraded Toyota's credit rating AA1 from AAA. This means Toyota has to borrow at higher interest rates and spend up to 220 million USD annually. However, Toyota is not committed to giving up its commitment to the job guarantee policy for its employees.

2.2. Explain why Toyota has existed for nearly 150 years and almost never fired a single person?

Kaizen used by Toyota. This is inherently a system that was born at the place of production. But this philosophy is also seen as the system for training people to think. Through that, Toyota creates opportunities for employees to develop their intelligence.

In order for someone to act, they must be the contributor. When they give their own opinions, they will be confident and know how to act in a positive way.

The question is how does one contribute an opinion? Simply, the leader should deliberately "make it difficult" for them a little. Once faced with a challenge or difficulty, people are forced to think and come up with a solution to the problem.

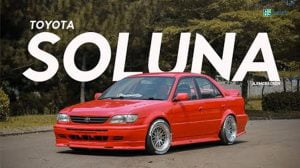

2.3. Interesting story about the birth of Soluna

When embarking on the design and construction of a strategic vehicle line in Asia, the Tercel series (also known as Soluna in Thailand). Mr. Takeshi Yoshida, chief engineer, gave an interesting way as follows:

The Soluna series is intended to be sold in Thailand. The requirement here for the engineers was to design a model with a lower selling price at the time than the Corolla line. However, in the perception of many employees, the Corolla is the lowest level of Toyota's models.

Therefore, employees can not imagine what if producing cars under the Corolla line-up would be. So when asked: “Can we remove any part from Corolla?” Then everyone replied no.

It wasn't long before Mr. Yoshida deliberately made a very cheap and bad model to show them. When "admiring" this "rag" car; A series of comments were made.

From Mr. Yoshida's bad idea, many good ideas were created from everyone. And as a result, the Soluna model was born.

Toyota-style Kaizen is taking human intelligence as the root. The role of the leader is to create the environment to “pull and pull” those minds and bring them together. Accumulating small Kaizens will produce unexpected results in the long run.

3. What are the benefits of enterprises when applying Kaizen?

When Kaizen be applied flexibly and reasonably to enterprises; It will bring many tangible and intangible benefits. Advantage of Kaizen What is that? Let's find out with DPS!

3.1. Tangible benefits for businesses

There are 2 typical tangible benefits for businesses when successfully applying Kazen.

Firstly, your business will reduce waste; At the same time, it increases the productivity of your business. In Toyota's case, Kaizen It helps the company to cut costs such as: inventory, lead time, transportation and excess production in factories.

Secondly, businesses can also improve their operations during their operations. Indeed, at Toyota's manufacturing plants, workers don't waste time sorting through parts. They just use plastic baskets for sorting. In addition, they also build their own trucks from the parts already in the line and just install the engine. Thanks to that, Toyota was able to save about 3000 USD on the cost of buying a cargo vehicle.

It can be seen that the business will be able to accumulate every smallest improvement in the long run; and then create even greater results.

3.2. Intangible benefits for business development

Not only bring tangible benefits but Kaizen It also brings 3 outstanding intangible benefits to businesses.

The first is that each employee is encouraged and motivated to come up with good ideas that bring many effective improvements in the business.

The second benefit is, improving the team spirit for all employees. At the same time, it also increases solidarity within the enterprise.

Finally, forming a culture of thrift and continuous improvement in the enterprise.

4. Steps to implement Kaizen.

By now you should have basically understood Kaizen what is it right! In the next step, DPS will show you how to effectively apply the philosophy to your business!

Kaizenis performed based on the cycle PDCA (Plan - Do - Check - Action). And it's encapsulated in 8 steps. More specifically, the steps Kaizen include:

Step 1: Select the scope of application of Kaizen.

Businesses should pay attention when choosing the scope to apply Kaizen. Here, the scope can be a production line or a specialized department. And you should make sure it's feasible to make improvements.

For greater certainty, test this philosophy at a certain point; and then you can scale it up slowly until you reach enterprise-wide scale.

Step 2: Find out the current situation and define goals for the business.

Before creating a communication strategy IMC or any strategy, you always need to find out and evaluate the actual state of your business. From there, you can come up with a more unified, basic and feasible goal.

This will help your business avoid waste problems, make efficient use of resources and unfinished plans.

You should remember that Kaizen is a philosophy, not a tool. Therefore, it requires a long-term commitment and effort of every member and every level in the business.

Step 3: Analyze the collected data and determine the root cause.

After collecting relevant and necessary data, the leadership should meet together to review and evaluate the current situation of the business. Most importantly, they can jointly identify the root causes of the problem.

Step 4: Based on data analysis to determine implementation measures

Once the root of the problem is found, the next step is to come up with a solution. Parallel to the solution are the criteria and tools to measure the achieved results.

Step 5: Implement Kaizen Measure

This is the step where philosophy Kaizen applied according to the original plan. In the process of implementation, the management should create a suitable environment for employees to contribute ideas. At the same time, they are also the one who gathers appropriate opinions, regularly checks, and monitors the application in practice.

Step 6: Confirm the results of the measures taken

Once the action has been taken, the business needs to collect relevant data. For the purpose of measuring and evaluating performance. In this step, you will use the appropriate tool to compare the results achieved with the criteria set out in Step 4.

Step 7: Develop or revise standards to overcome weaknesses

Once the results are evaluated, businesses can find some disadvantages or inappropriate points when applying Kaizen into business practice. Immediately, management can make adjustments or more appropriate measures. In order to avoid the application Kaizen mechanically into your business.

Step 8: Review the above processes and determine the next project

As DPS emphasized above, Kaizen is a philosophy that takes a relatively long time to see results. Remember that and businesses should not be in a hurry but have to be patient in doing the smallest things and gain deep experience through each implementation. Doing this surely in the long run, businesses can reap greater achievements.

5. Factors determining success when implementing the Kaizen philosophy.

Understanding Kaizen What is one thing. But when it comes to practice and success is another story. Because, this philosophy is also influenced by three important factors:

5.1. Commitment from top management

In class Kaizen, the leadership role is particularly focused. Because, the leader is the one who steers the "boat". They need to create the right environment for employees to generate ideas such as:

- Working group.

- Network management.

- Invest in gray matter.

- Training Employees.

5.2. The role of the manager and team leader

For team leaders or managers, they need to maintain and continuously improve current standards in technology as well as production management. This is aimed at achieving higher labor productivity. Then the business results are better.

5.3. Everyone's efforts to participate

The success of the application Kaizen into the enterprise is very determined by the participation and contribution of all employees. Regardless of their level, they must be aware of the importance of this philosophy. Every employee in the organization strives to participate and contribute ideas to establish a new system of thinking and to build a business environment in the right direction. Quote: “If you want to go fast, go alone. If you want to go far, go together” is very true in this case.

6. What are the principles of Kaizen when applied?

Why, philosophy? Kaizen It has become as widespread as it is today because it possesses principles that are immutable over time. Once the business has applied Kaizen must strictly comply. No matter the size of your business is small or large. In more detail, Kaizen has the following 10 principles including:

Principle 1: Always focus on customer benefits

All products or services of the business created must meet the needs of the target customer. Therefore, businesses need to focus on improving little by little in the quality of their products or services. At the same time increase the benefits of the product; The ultimate goal is to create maximum satisfaction and satisfaction from customers.

Principle 2: Continuously improve

Completing the original goal does not mean the improvement work is over. This is just the end of a phase; before moving on to the next stage.

Because customer demand will increase more and more in the future. Therefore, if you do not want to be eliminated from the market, businesses need to constantly improve to improve product quality. It helps businesses save time and money. At the same time, businesses can be ahead of the curve or create trends. That is, creating needs for customers even if they do not realize their needs.

Principle 3: Build a no-blame culture

Each employee is assigned a specific task. When making a mistake or not completing the assigned task, the responsibility should be attributed to the right person. Do not blame others or give unwarranted reasons.

Principle 4: Promote an open corporate culture

Open corporate culture here is understood when employees dare to look directly at their own flaws and shortcomings. If an employee needs help from a colleague or superior, they need to actively seek help from everyone.

Therefore, businesses need to establish an internal communication network. A place where employees can help, learn and share experiences from each other.

Principle 5: Encourage teamwork according to the Kaizen philosophy

Enterprises should orient to build a human resource structure according to effective teams, instead of working individually.

When setting up groups, it is necessary to clearly decentralize authority. At the same time, they need to have conventions to resolve conflicts that occur in the team.

In which, the team leader needs to have leadership ability. While each team member needs to respect each other's conventions and personalities.

Principle 6: Combine multiple departments and functions in the same project

When implementing any project, businesses should allocate and combine human resources from other departments. If necessary, you can fully utilize external resources.

Principle 7: Create the right relationships among all employees

To not create confrontational or hostile relationships; Enterprises need to invest in training programs on employee communication skills. In addition, businesses can organize team-building sessions to tighten the relationship between employees.

The building of relationships among employees; The same goes for building a culture at your business.

Principle 8: Cultivate a sense of discipline and self-discipline

Build and train employees with a sense of discipline as well as a spirit of self-discipline to comply with the rules at the enterprise.

Besides, employees also need to put the interests of work first. From there, they can self-assess and re-examine themselves. This is for them to be able to improve themselves and overcome their weaknesses.

Principle 9: Communicate to all levels and employees

If you want to achieve high results at work; Businesses should be transparent with their employees.

Because information is the most important factor to make mistakes and "flow" throughout the business process. Information communicated well internally would be the perfect way; for businesses to share common difficulties and challenges with all employees in the organization.

Principle 10: Boost productivity and efficiency

Simultaneously deploying and synthesizing internal training methods to all departments in the enterprise.

In each project, it is necessary to assign specific and clear permissions for each position to each team member. Each individual has to promote his or her own ability, proactively give suggestions and feedback.

When there are achievements, businesses need to recognize and reward promptly to all team members. This will stimulate capacity as well as improve working efficiency on an enterprise-wide scale.

Hope the above article has provided you with useful information around philosophy Kaizen. Good luck applying any philosophy to your business!

Reference source:

Álvarez-García, JD-S. (2018). Systematic bibliometric analysis on Kaizen in scientific journals. The TQM Journal.

Carnerud, DJ (2018). Kaizen and continuous improvement–trends and patterns over 30 years. The TQM Journal.